The process of palletization to place ceramic tiles upon pallets form moving ceramic and transport ceramic by means of pallets, is part of the production process of tile industry, a chain of linked functions in classification and packaging.

As ceramic manufacturer in the tile market we feel that every part of the ceramicpath is vital. Organising ceramic, storing materials, a correct palletization, are all importan sequences in the manufacturing process. Each of these stages requires precision and expertise to produce high-quality ceramic products that meet the desired specifications.

What do you know about the Ceramic Fabrication Process?

The ceramic fabrication process involves several intricate steps to transform raw materials into finished ceramic products. The process typically includes the following stages:

- Raw Material Preparation: The process begins with the selection and preparation of raw materials such as clay, quartz, and other minerals. These materials are often finely ground and mixed to achieve the desired properties.

- Shaping: Once the raw materials are prepared, they are shaped into the desired form. This can be accomplished through methods such as molding with shaped containers.

- Drying: The shaped ceramic pieces are carefully dried to remove moisture. This is a crucial step to prevent cracking or warping during the subsequent firing process.

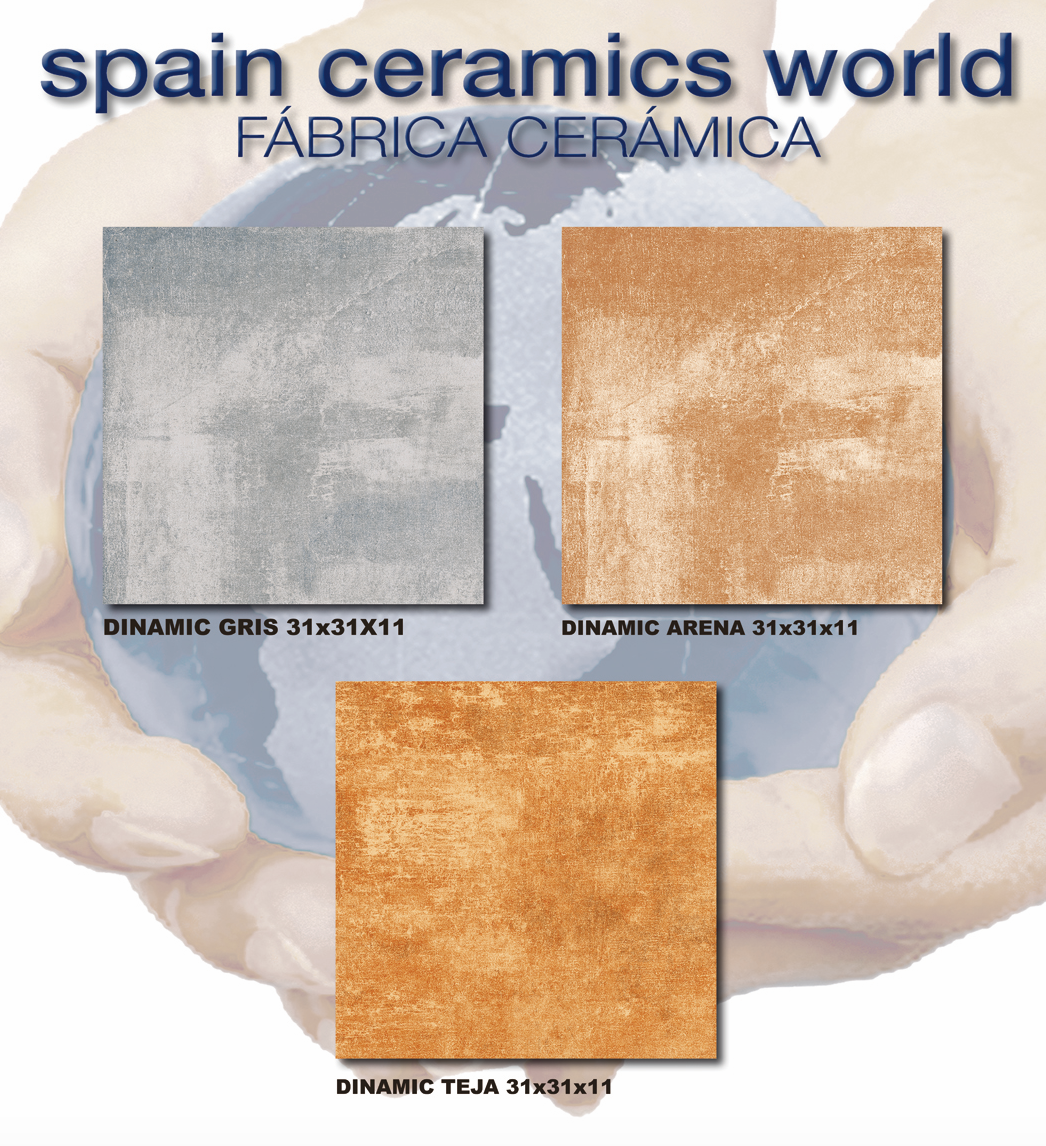

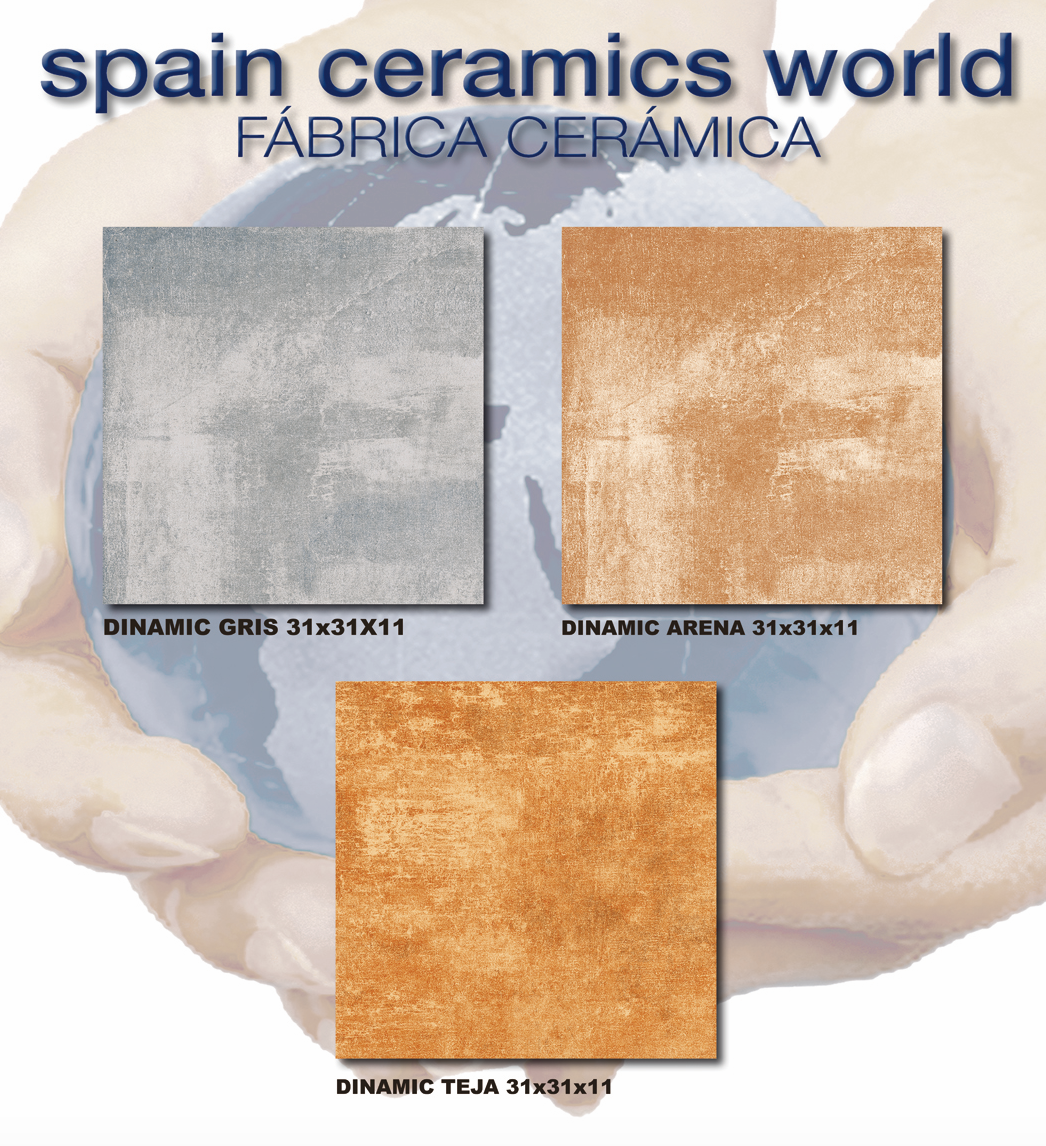

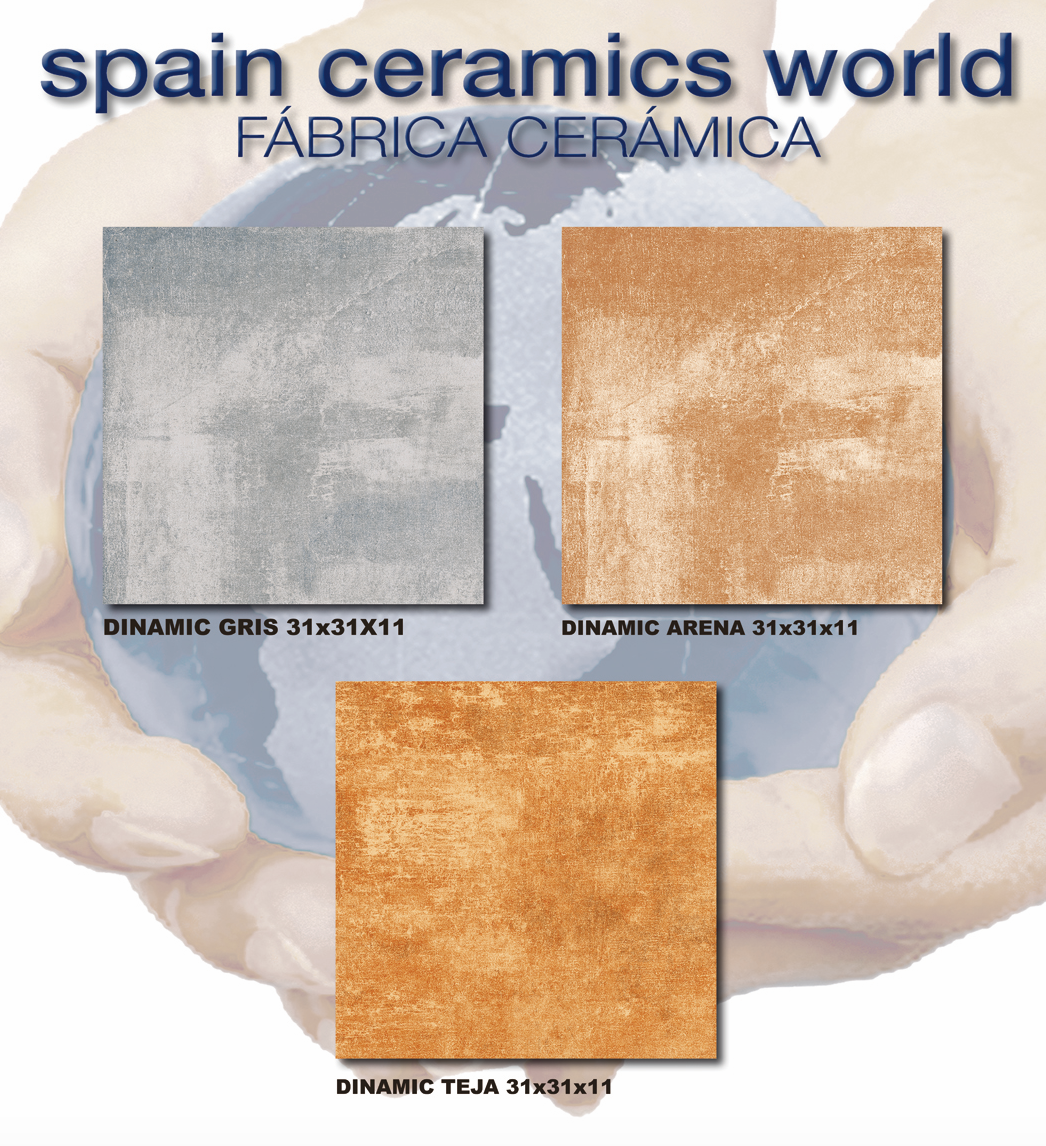

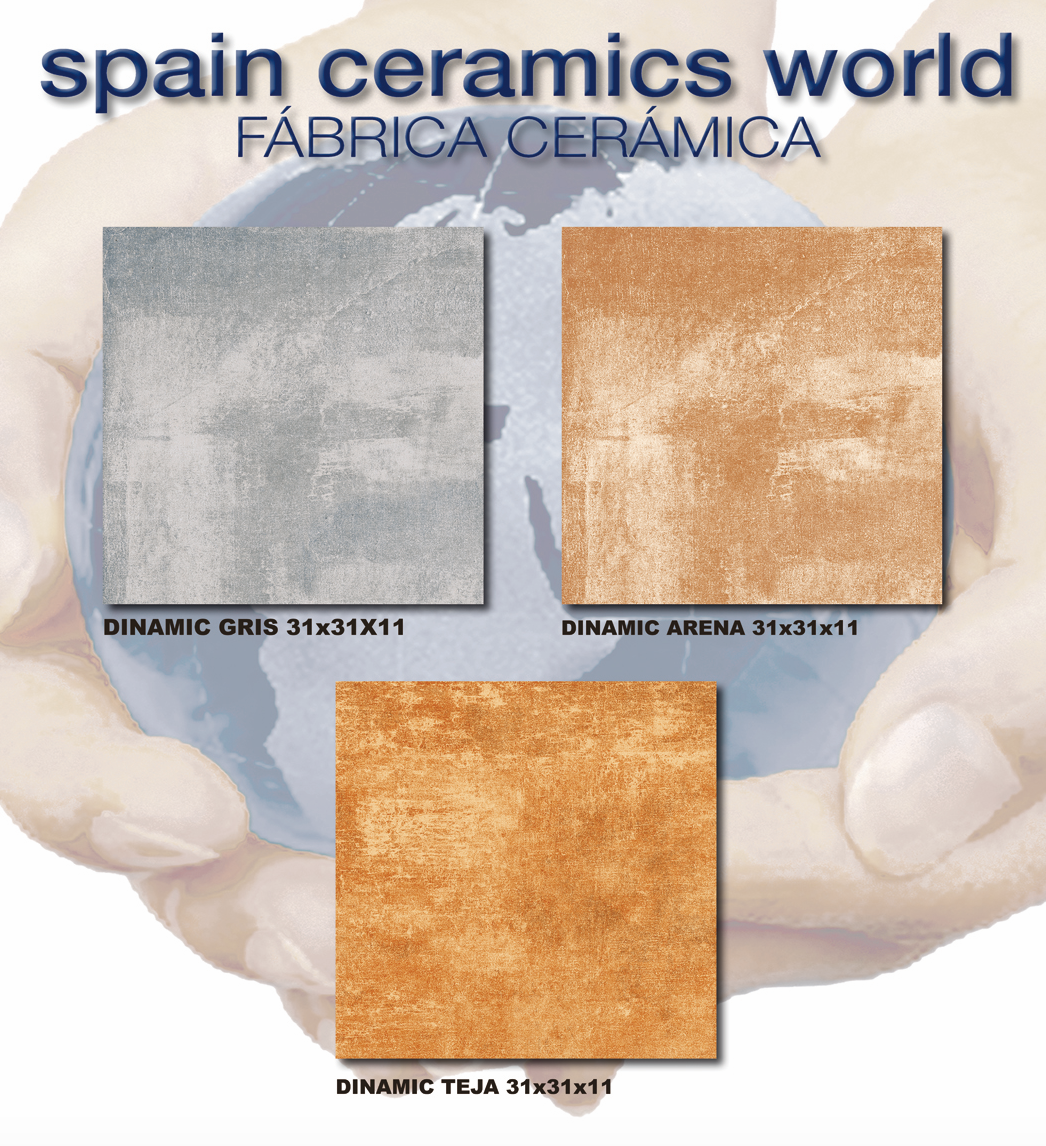

- Decoration : Depending on the desired design, decorative elements may be added at this stage, such as glazing, painting, or carving.

- Firing: The dried ceramic pieces undergo a high-temperature firing process in a kiln. This firing process is essential for hardening the ceramic and enhancing its strength and durability.

- Quality Control: After the firing process, rigorous quality control measures are often implemented to ensure that the finished ceramics tiles meet the required standards for strength, appearance, and functionality.

- Final Finishing: Any final touches or finishing processes, such as polishing or assembly, are carried out before the completed ceramic tiles are ready for distribution or use.

Palletizing is part of the process, you can watch the short video that showcases a brief sequence of the ceramic fabrication process in action in our fabric in Spain . Learning about the ceramic time production through visual representation can offer you valuable insight into the process involved in creating ceramic tiles.

Staff machines spend the morning putting ceramic on boxes. Robotic palletization at Spain Ceramics World. The line of the ceramic.